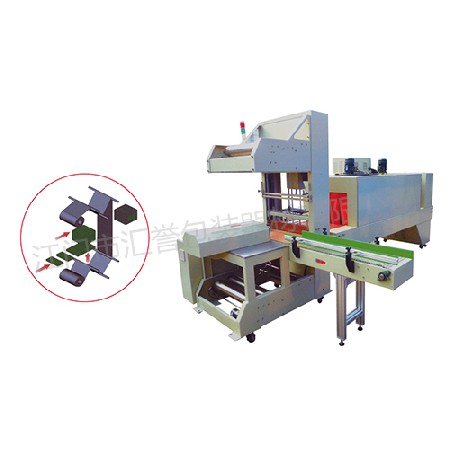

HY-6030A HY-6040E fully automatic cuff type (integral type) sealing, cutting and shrinking packaging machine

2020-12-11 1375

Product Features:

The HY-6030A HY-6040E fully automatic cuff packaging machine is designed for individual objects or items with paper trays. This machine can be connected to the production line for automatic feeding, film wrapping, sealing, shrinking, cooling and shaping, achieving unmanned flow operation;

HY-6030A introduces technology and process manufacturing, with stable and reliable equipment performance, and can automatically calculate daily production;

☆ Inductive film feeding greatly reduces film loss;

☆ Original Ottonius digital temperature controller, precise temperature, can directly see the temperature status during sealing and cutting;

☆ Stepless mechanical speed control device, adjusting the speed of the feeding conveyor belt;

☆ Adopting Schneider PLC programmable controller and intelligent touch screen matching to achieve the integration of machine, electricity, and gas;

☆ Adopting a specially designed three piece sealing knife, the sealing line is firm, non cracking, and not easy to stick to the knife;

The feeding conveyor belt can be designed to feed on the left or right side as needed;

The HY-6040E adopts a dual air motor, with a large air flow cooling airflow to evenly distribute hot air in the furnace compartment, and the product quickly cools and solidifies after thermal shrinkage;

☆ The conveying adopts a frequency converter to control the conveying speed, with stepless speed regulation;

☆ Super large air volume cooling airflow, quickly cooling and shaping the product after heat shrinkage;

The whole machine adopts Schneider frequency converter from France to control the transmission speed, with stepless speed regulation;

☆ Suitable for collective or single shrink packaging of beverages, beer, mineral water, cans, glass bottles with paper holders, cardboard and color box integrated products, etc.

-

11-07

Jiangmen Packaging Materials: How to Choose Buffer Packaging Materials

There are many kinds of cushioning packaging materials on the market, mainly including inflatable bags, pearl cotton, foam boards, bubble films, etc., which are commonly used to package various produc

-

11-07

Jiangmen Packaging Equipment: What are the Common Packaging Materials

1. Single powder (white card)1. Commonly used paper box materials, with paper thicknesses ranging from 80g to 400g, and higher thicknesses requiring two sheets to be laminated.2. The paper has a gloss